About Us

We are a team of five designers with backgrounds in mechanical engineering, controls and electrical engineering. We primarily help companies with product development, design for manufacturing and production tools/automation. We call Seattle, Washington our home but have no problem working with companies around the world. We have low overhead costs and provide high quality work with rates at 1/3 the cost of many larger design and engineering firms.

Design

We team brainstorm with rough sketching. After we 3D model, with design reviews and prototypes/feasibility testing to iterate.

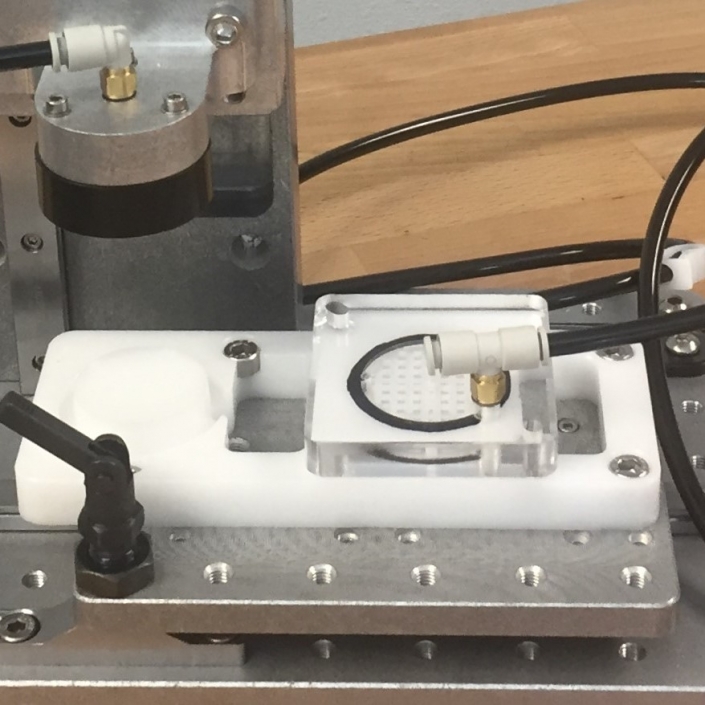

Test

We build, test and redesign to make sure your product or tool functions the way you need it to. We don’t just make things that look pretty, we make things that work.

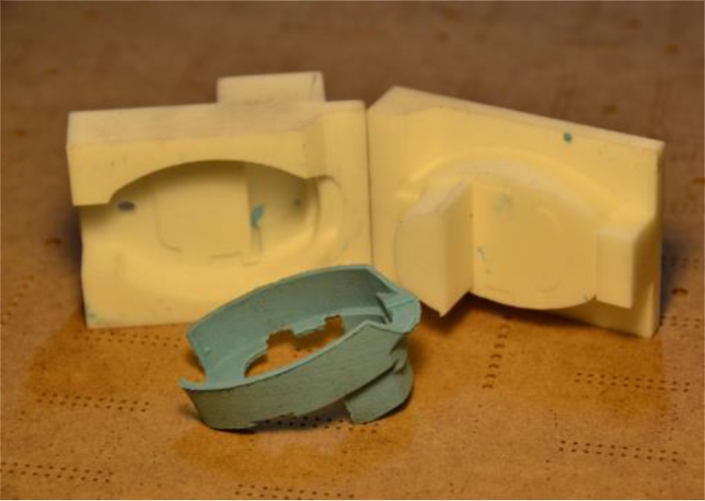

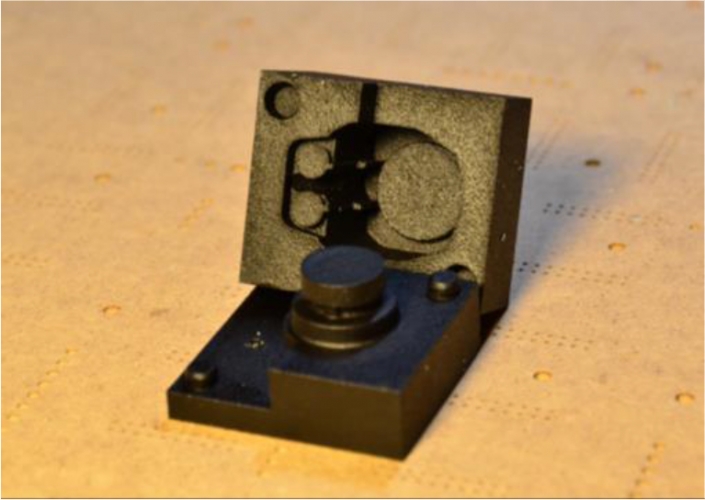

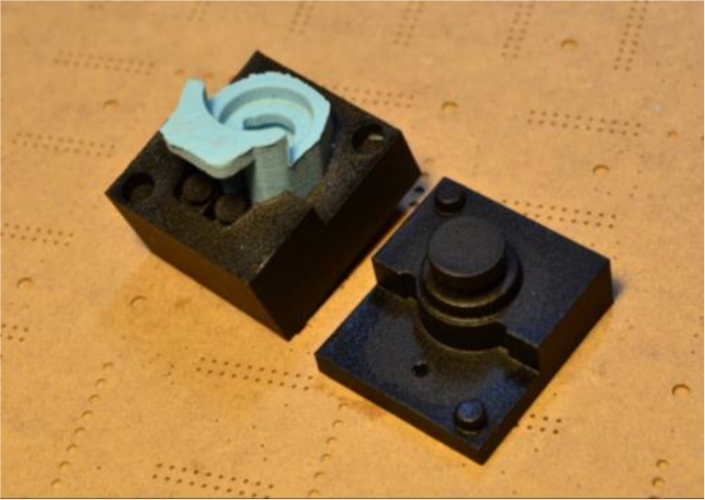

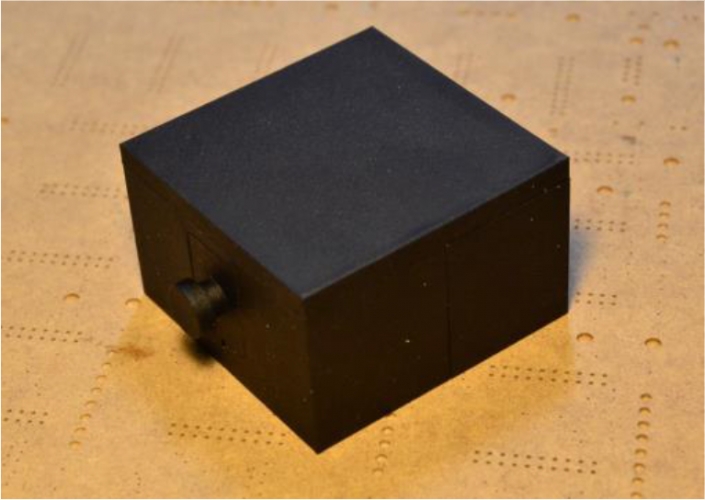

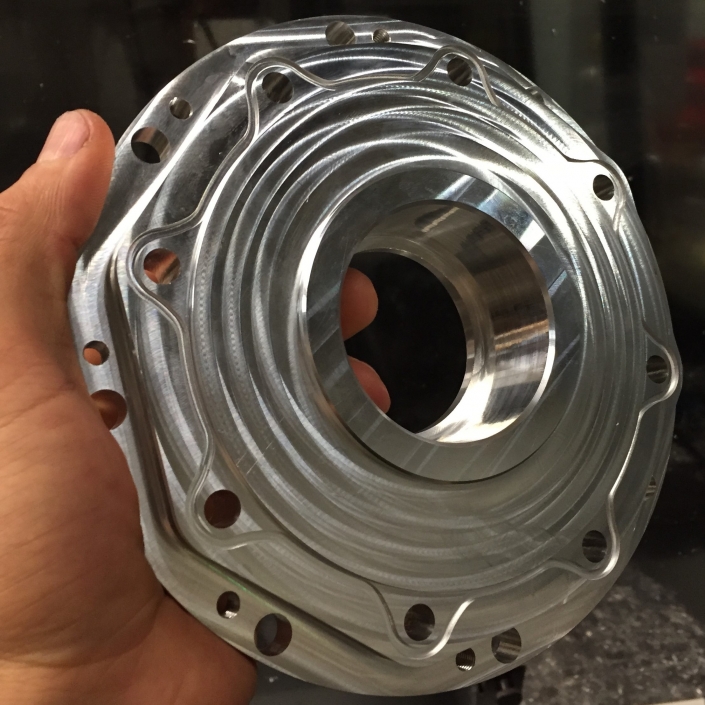

Prototype

Whether the development drives with 3D printed assemblies or tight tolerance machined parts, we can build it. Checkout the list of technologies we’ve had experience with below.

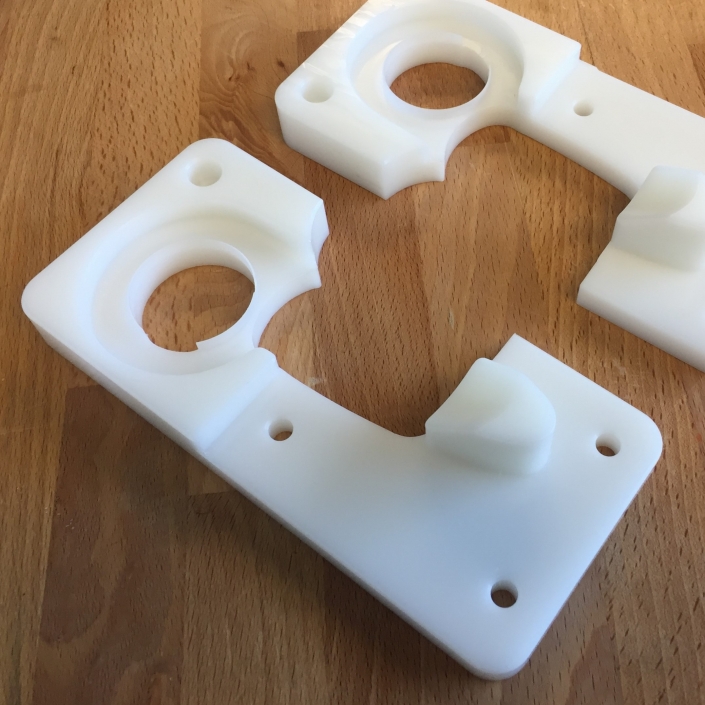

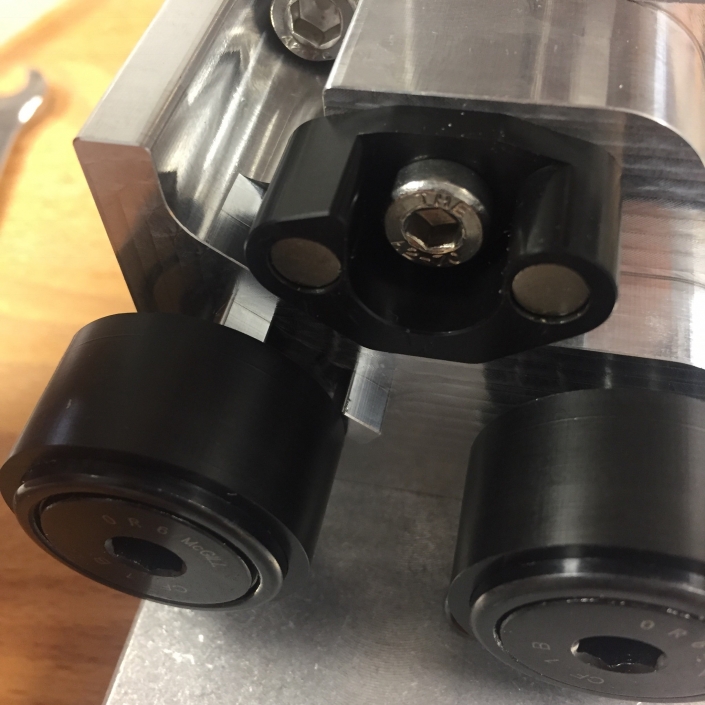

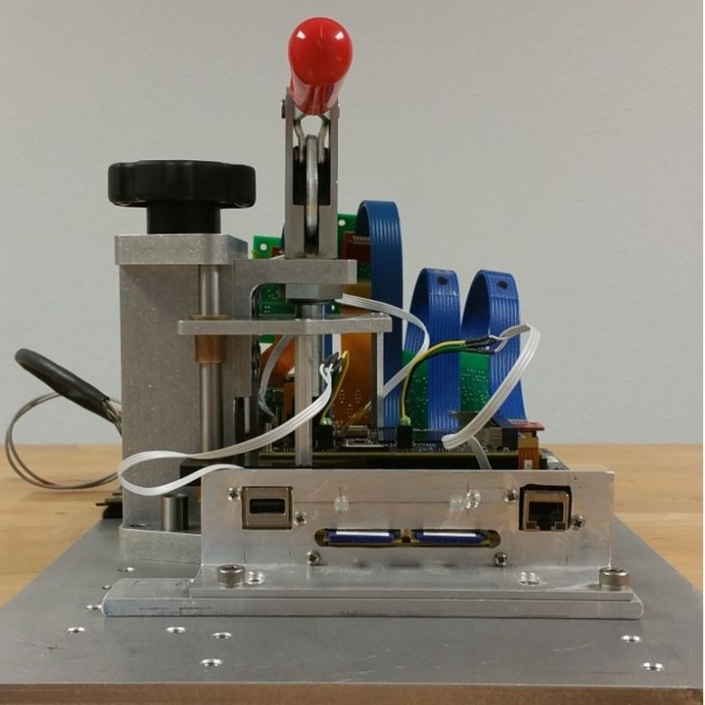

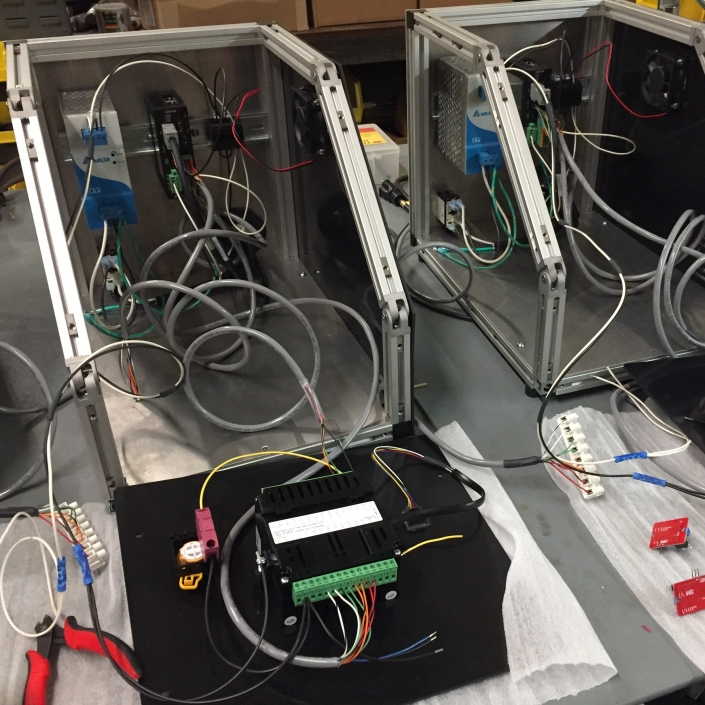

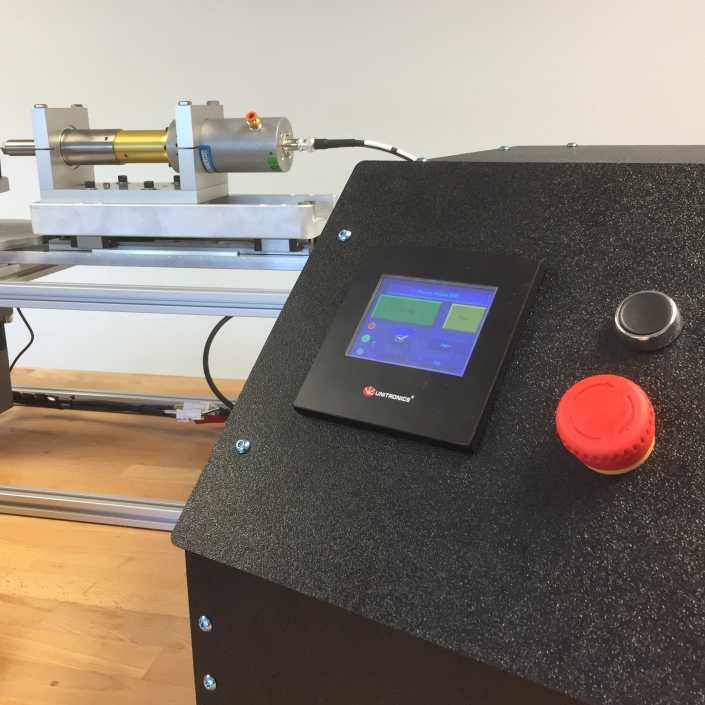

Tooling and Automation

We have all had our hands in many automation and tooling projects over the years. We can make complex automated machines and elegant fixtures to meet your demand.

Preproduction & Production

We have sourced all kinds of parts, injection molded, sheet metal, machined and cast to name a few. We can find you good domestic and international suppliers and make sure your parts come out right.